Demil

Ecologia Soluzione Ambiente is a multiple-business entity operating in the environmental sector and in the demilitarization of conventional and nonconventional weapons.

Ecologia-designed demilitarization systems have so far contributed to the demilitarization of the entire Italian stock of antipersonnel mines (banned in 1997 - Ottawa Treaty) and the destruction of large stockpiles of cluster munitions (banned by the Dublin process - 2008), including the disposal of HE submunitions and rocket/missiles propellant.

check out the brochure

Tailor-made Solutions

We propose complete, safe and integrated systems for modern industrial demilitarization needs, including the disassembly, the recycling and, when necessary, the controlled disposal of explosives and propellants. In addition, we offer global support services for any industrial Demil process.

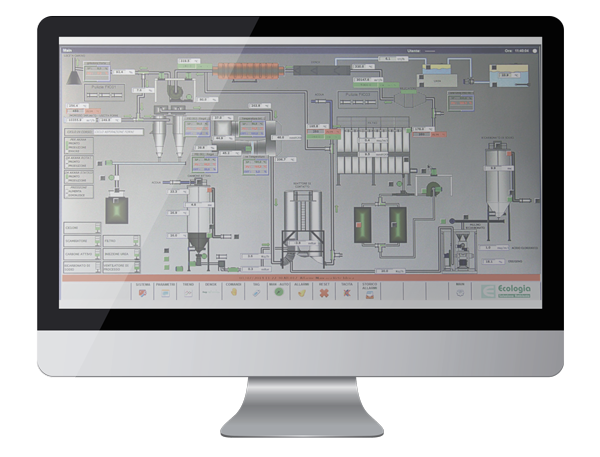

Real Time Monitoring

Our systems are thus equipped with advanced remote controls and monitoring devices. Ecologia’s complete production lines are highly automatized and allow for reduced energy requirements and low manpower demand.

International Standard

Thanks to its experience and know-how, ESA develops highly technological solutions, compliant with the international standards in terms of Safety and Environment. We design and develop safe, cost-effective and environmentally-friendly processes for the demilitarization of weapons.Modern industrial demilitarization, in our opinion, cannot in any way disregard those aspects.

Technologically Adavanced Solutions

We design our lines paying the utmost attention to economic sustainability, both in terms of design and installation costs (CAPEX) of operating costs (OPEX). The economic sustainability of systems is thus maximized together with the quality parameters (Health, Safety, Environment, Efficiency). Thus, we are ready to develop joint demilitarization programs with our Clients and therefore sharing financial risks and benefits in a close partnership framework.

Examples of our products, fully customizable and designed at the highest HSE standards are:

Thermal disposal and environmental/safety controls:

- High-capacity thermal disposal ovens for propellant and explosives (e.g. 300/500 kg/h – STD-300/500

- Armored kilns for the deactivation of complete ammunition (e.g. 30.000 items/h – RTD- 30K)

- Advanced complete off-gas treatment and monitoring (SCR, CTO, multi-stage neutralization of acids, thermal/catalytic afterburners, HP filtration), from 1.000 to >100.000 Nm3/h

- Sistemi di monitoraggio e di risposta immediata per la Demil di armi chimiche

Recovery/recycle of explosives:

- Melt- Steam- or Wash-out of explosives for recycling

- Cryofracture.

- Purification systems

Mechanical processing:

- De-priming, pull-apart, delinking, macchine da taglio

- De-priming, pull-apart, delinking, cutting machines

Pollution mitigation systems:

- Red water treatment - waste water treatment

- water recycling/reuse

- energy recovery

Combination of technology in complete demil lines

Commissioning and Management Service

Design

ESA develops its design in an interactive way, to attain the optimal convergence between our Client needs and the actual system specification.

Commissioning

ESA provides full commissioning support to our Clients in order to achieve full compliance with the production and efficiency goals.

Full Industrial Support

ESA offers post-commissioning customer support, in flexible modalities: from periodic maintenance to full industrial management of the systems, to reach and maintain full efficiency and production rate.

Post-sales Management

The delicate nature of this question forces our team to be always on-call and able to provide quick solutions to any type of need.

That is why we created Demil Customer Service, a specialized unit aimed at providing assistance through highly-skilled and well-trained technicians.